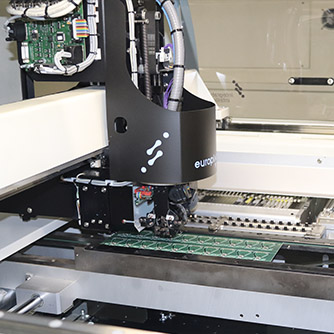

We run twin Europlacer based SMT technology. Both feature fully automated screen printing (including paste inspection) and multi-zone reflow ovens. One line also incorporates automatic board handling to support higher volume requirements. All Surface mount assemblies pass through Automatic Optical Inspection.

Programs are stored centrally and shared between the lines. The common platform for our surface mount device, along with an intelligent trolley based loading system, mitigates any risk associated with a breakdown, as all circuits can be run on either line.

Our electronic contract manufacturing services have a long and successful history of SMT placement. Twenty years ago, we placed our first BGAs. Over time, these have become micro BGAs, along with LGAs, QFNs, CSPs and all are now commonly used.

We are able to place packages from 01005 up to 99mm2. Odd form components are a Europlacer speciality.

Maximum feeder capacity is 264 x 8mm reels, meaning very large BoMs cause no issue. Tubed and trayed components are also handled with ease.

Components per hour placement rate

The smallest chip device that we currently place

Maximum SMT line items per circuit side.

“We have enjoyed an excellent commercial and technical relationship for 20 years with Camtronics. They have supported us in manufacturing and in continuously developing competitive products that keep us at the forefront of the industrial and automotive industry.”

Global industrial sensor & control company

“Throughout our ten-year partnership, we have always valued Camtronics’ commitment to flexibility and communication.

Their collaborative and proactive approach is a major benefit to us and we value the high quality of the increasing number of products they manufacture on our behalf”

Leading UK bio-pharma company

“Camtronics have handled small, one-off panel sample orders right through to large scale production volume orders … and deliveries have always been met.

Communication is a key aspect for us and we have entered into a strong working relationship, one that will hopefully last for a long time.”

Market leading industrial processing company

“Keep up the good work.”

UK based environmental science company

“We love you guys!”

Innovative data logger manufacturer